AD 55T All-Electric Injection Molding Machine

Description

Download

|

Model |

AD55T |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Clamping force |

kN(tf) |

540(55) |

|||||||||||

|

Space between tie bar |

mm*mm |

360*310 |

|||||||||||

|

Plate dimension |

mm*mm |

500*540 |

|||||||||||

|

Opening Stroke |

mm |

250 |

|||||||||||

|

Mold thickness |

mm |

160~350 |

|||||||||||

|

Positioning ring |

mm |

100 |

|||||||||||

|

Ejection force |

kN(tf) |

21(2.1) |

|||||||||||

|

Ejection Stroke |

mm |

70 |

|||||||||||

|

Injection system |

|||||||||||||

|

Screw diameter |

mm |

18 |

20 |

22 |

20 |

22 |

25 |

22 |

25 |

28 |

25 |

28 |

32 |

|

Shot weight(GPPS) |

oz |

0.63 |

0.77 |

0.945 |

0.91 |

1.12 |

1.44 |

1.33 |

1.72 |

2.14 |

1.72 |

2.14 |

2.8 |

|

g |

18 |

22 |

27 |

26 |

32 |

41 |

38 |

49 |

61 |

49 |

61 |

80 |

|

|

Rubber melting speed |

r/min |

400 |

400 |

400 |

400 |

||||||||

|

Injection distance |

mm |

73 |

87 |

104 |

104 |

||||||||

|

Nozzle Protruding |

mm |

30 |

30 |

30 |

30 |

||||||||

|

Nozzle contact force |

kN |

11 |

11 |

12 |

12 |

||||||||

|

Injection unit |

S67L |

S85L |

S105L |

S135L |

|||||||||

|

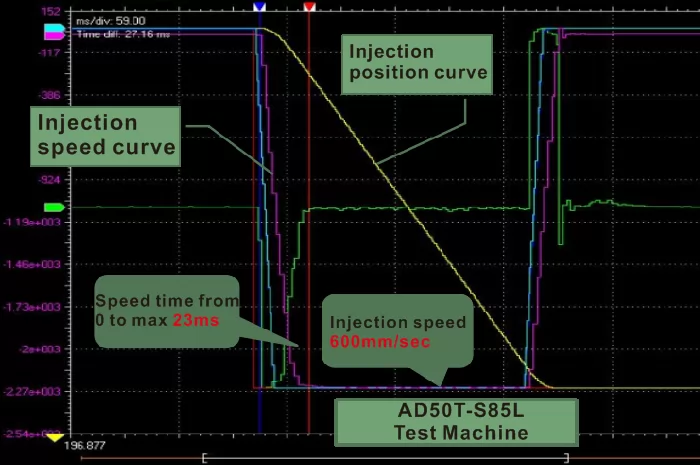

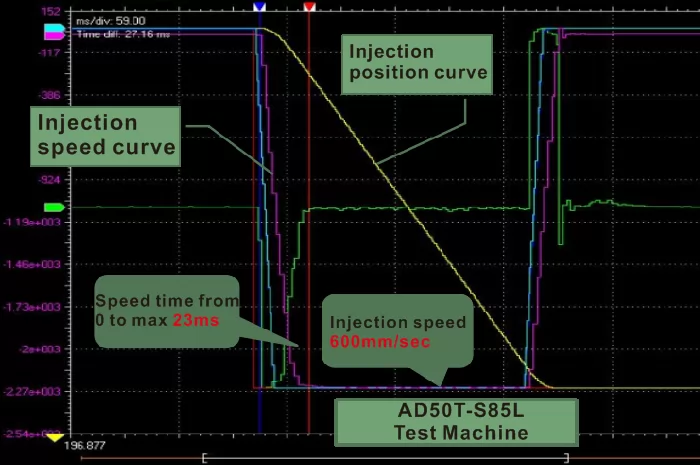

Injection speed |

mm/s |

600 |

600 |

500 |

500 |

||||||||

|

Injection rate |

cm³/s |

153 |

188 |

228 |

188 |

228 |

294 |

190 |

245 |

308 |

245 |

308 |

402 |

|

Injection pressure |

MPa |

280 |

224 |

179 |

280 |

224 |

179 |

285 |

221 |

180 |

282 |

224 |

172 |

|

Holding pressure |

MPa |

224 |

179 |

143 |

224 |

179 |

143 |

228 |

177 |

144 |

225 |

179 |

138 |

|

Plasticization capacity |

kg/h |

10 |

13 |

18 |

13 |

18 |

26 |

18 |

26 |

37 |

26 |

37 |

53 |

|

Injection unit |

S67M |

S85M |

S105M |

S135M |

|||||||||

|

Injection speed |

mm/s |

300 |

300 |

250 |

250 |

||||||||

|

Injection rate |

cm³/s |

76 |

94 |

114 |

94 |

114 |

147 |

95 |

123 |

154 |

123 |

154 |

201 |

|

Injection pressure |

MPa |

280 |

224 |

179 |

280 |

224 |

179 |

285 |

221 |

180 |

282 |

224 |

172 |

|

Holding pressure |

MPa |

224 |

179 |

143 |

224 |

179 |

143 |

228 |

177 |

144 |

225 |

179 |

138 |

|

Plasticization capacity |

kg/h |

10 |

13 |

18 |

13 |

18 |

26 |

18 |

26 |

37 |

26 |

37 |

53 |

|

Other |

|||||||||||||

|

Machine Dimension |

mm*mm*mm |

3650*990*1700 |

3650*990*1700 |

3650*990*1700 |

3650*990*1700 |

||||||||

|

Machine weight |

T |

2.2 |

2.3 |

2.4 |

2.4 |

||||||||

|

|

|

|

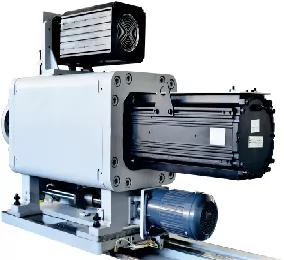

Heat cover

Adopt double-deck heat cover of

stainless steel.Reduce energy

consumption of heating system.

Avoid operator be scalded due

to mishandling.

|

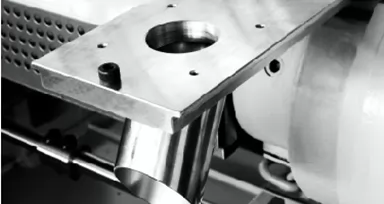

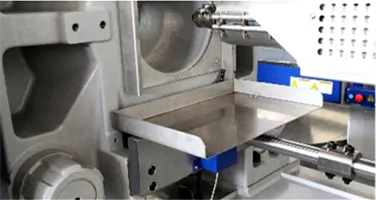

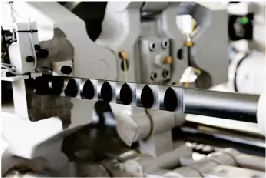

Injection safety protector

Reasonable design which avoids operator

being scalded due to mishandling and

facilitates operation,greatly improves work

efficiency.

|

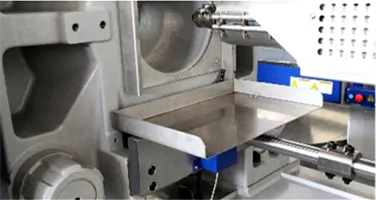

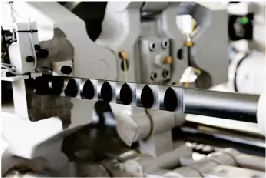

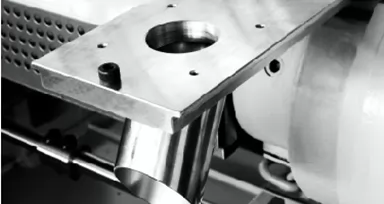

Material clean-up plate

Configured stainless steel cleaning

plate under the nozzle to facilitate

waste removal,avoiding waste being left

on the gap of machine while clean-up operation

Less troubled during maintenance.

|

|

|

|

|

Chute type erecting bed for hopper

Humanized design .easily installed;

Adopts high-quality steel.stronger

and make it more durable ,safely

and reliably to use.

|

Color touch display

15 inch HD color touch display ,

its clear image makes it handy to operate,

rotatable design which is more convenient

for technical operation.

|

Three-color alarm light

When emergency occurs,the device will

remind you what kind of situation by

different colors ,you can cope with urgent

situations more easily,greatly increase the

production management efficiency.

|

|

|

|

|

|

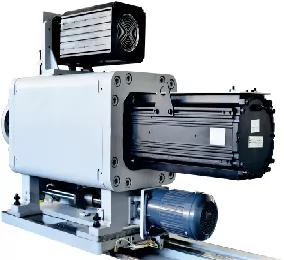

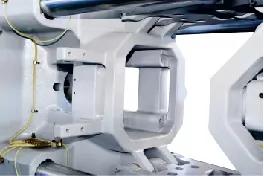

Direct-drive closing mold

Direct drive mechanism,quick response

for opening and closing mold.excellent

protection for low pressure.

|

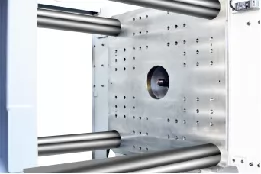

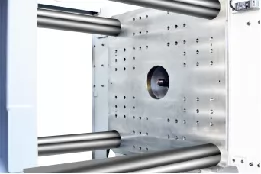

High standard clamping unit

High standard clamping force

and parallelism adjustment are

achieved with stable clamping

state and reduced mold losses.

|

Support plate

High wear resistance and low

friction of the movable plate

supports sliding block, extends

mold service life.

|

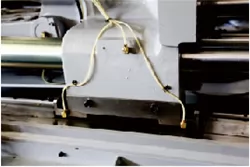

Full-automatic lubricating device

Reduce cost of maintenance。

|

|

|

|

|

|

Fixed plate structure

Optimized fixed plate structure.

reduces the tilting deforming of plate

|

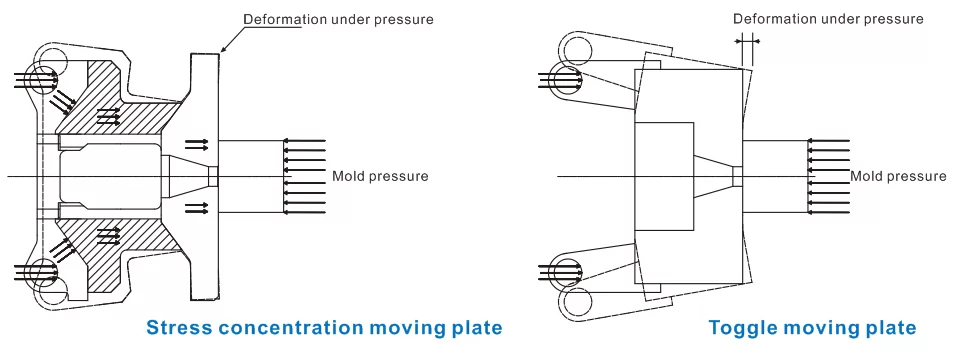

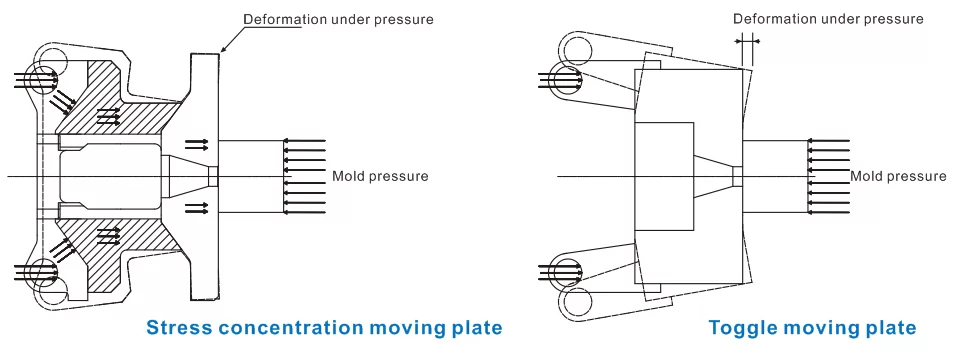

Stress concentration moving plate

Optimized moving plate structure,

significantly improving the precision

of locking face.

|

Machinery safety bar

Reliable machinery safety bar.

|

Frame

High strength frame design and adopt

thick wall structure stesl components,

reducing the vibration of fast opening

and closing.

|

|

Model |

AD80T |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Clamping force |

kN(tf) |

780(80) |

||||||||

|

Space between tie bar |

mm*mm |

410*360 |

||||||||

|

Plate dimension |

mm*mm |

580*530 |

||||||||

|

Opening Stroke |

mm |

300 |

||||||||

|

Mold thickness |

mm |

160~410 |

||||||||

|

Positioning ring |

mm |

100 |

||||||||

|

Ejection force |

kN(tf) |

26(2.7) |

||||||||

|

Ejection Stroke |

mm |

80 |

||||||||

|

Injection system |

||||||||||

|

Screw diameter |

mm |

22 |

25 |

28 |

25 |

28 |

32 |

28 |

32 |

36 |

|

Shot weight(GPPS) |

oz |

1.33 |

1.72 |

2.14 |

1.72 |

2.14 |

2.8 |

3.01 |

3.96 |

5.01 |

| g |

38 |

49 |

61 |

49 |

61 |

80 |

86 |

113 |

143 |

|

|

Rubber melting speed |

r/min |

400 |

400 |

400 |

||||||

|

Injection distance |

mm |

104 |

104 |

104 |

||||||

|

Nozzle Protruding |

mm |

30 |

30 |

45 |

||||||

|

Nozzle contact force |

kN |

12 |

12 |

24 |

||||||

|

Injection unit |

S105L |

S135L |

S175L |

|||||||

|

Injection speed |

mm/s |

500 |

600 |

400 |

||||||

|

Injection rate |

cm³/s |

190 |

245 |

308 |

245 |

308 |

402 |

246 |

322 |

407 |

|

Injection pressure |

MPa |

285 |

221 |

180 |

282 |

224 |

172 |

285 |

218 |

172 |

|

Holding pressure |

MPa |

228 |

177 |

144 |

225 |

179 |

138 |

227 |

174 |

137 |

|

Plasticization capacity |

kg/h |

18 |

26 |

37 |

26 |

37 |

53 |

37 |

53 |

86 |

|

Injection unit |

S105M |

S135M |

S175S |

|||||||

|

Injection speed |

mm/s |

250 |

250 |

200 |

||||||

|

Injection rate |

cm³/s |

95 |

123 |

154 |

123 |

154 |

201 |

123 |

161 |

203 |

|

Injection pressure |

MPa |

285 |

221 |

180 |

282 |

224 |

172 |

285 |

218 |

172 |

|

Holding pressure |

MPa |

228 |

177 |

144 |

225 |

179 |

138 |

227 |

174 |

137 |

|

Plasticization capacity |

kg/h |

18 |

26 |

37 |

26 |

37 |

53 |

37 |

53 |

86 |

|

Other |

||||||||||

|

Machine Dimension |

mm*mm*mm |

3200*900*1680 |

3650*990*1700 |

3650*990*1700 |

||||||

|

Machine weight |

T |

1.9 |

2.3 |

2.4 |

||||||

|

|

|

|

Heat cover

Adopt double-deck heat cover of

stainless steel.Reduce energy

consumption of heating system.

Avoid operator be scalded due

to mishandling.

|

Injection safety protector

Reasonable design which avoids operator

being scalded due to mishandling and

facilitates operation,greatly improves work

efficiency.

|

Material clean-up plate

Configured stainless steel cleaning

plate under the nozzle to facilitate

waste removal,avoiding waste being left

on the gap of machine while clean-up operation

Less troubled during maintenance.

|

|

|

|

|

Chute type erecting bed for hopper

Humanized design .easily installed;

Adopts high-quality steel.stronger

and make it more durable ,safely

and reliably to use.

|

Color touch display

15 inch HD color touch display ,

its clear image makes it handy to operate,

rotatable design which is more convenient

for technical operation.

|

Three-color alarm light

When emergency occurs,the device will

remind you what kind of situation by

different colors ,you can cope with urgent

situations more easily,greatly increase the

production management efficiency.

|

|

|

|

|

|

Direct-drive closing mold

Direct drive mechanism,quick response

for opening and closing mold.excellent

protection for low pressure.

|

High standard clamping unit

High standard clamping force

and parallelism adjustment are

achieved with stable clamping

state and reduced mold losses.

|

Support plate

High wear resistance and low

friction of the movable plate

supports sliding block, extends

mold service life.

|

Full-automatic lubricating device

Reduce cost of maintenance。

|

|

|

|

|

|

Fixed plate structure

Optimized fixed plate structure.

reduces the tilting deforming of plate

|

Stress concentration moving plate

Optimized moving plate structure,

significantly improving the precision

of locking face.

|

Machinery safety bar

Reliable machinery safety bar.

|

Frame

High strength frame design and adopt

thick wall structure stesl components,

reducing the vibration of fast opening

and closing.

|